PU vs Epoxy - What’s the Reason for Different Resins?

03 Jan 2019

- The formulation of PU and epoxy systems makes them better suited to different environments

- Find out the key differences between the two main types of resin flooring

- Knowing when to apply the right floor is vital for contractors, architects and facilities managers

The two main types of resin floors are polyurethanes (PU) and epoxies – and understanding which is appropriate for different environments is very important for many construction industry professionals.

Each flooring system has differing properties suited to particular uses and choosing the wrong solution can result in costly repairs or even complete floor failure down the line.

While both are called resins, epoxy and PU floors should not be considered the same thing. Admittedly they do share similarities, such as being two-component systems (a resin and a hardener) that when brought together undergo a process of stoichiometric curing to form a solid layer. In both cases this results in a seamless, impervious coating that can be applied quickly in large quantities, but they are two very different types of materials with specific characteristics and uses.

The main difference between these two types of materials is in the molecular structure, which affects how it fuses together during the curing process. There are multiple types of components that can be used and that will vary the end result slightly, but essentially PUs have a higher cross-linked density than epoxies, making them the harder wearing of the two.

Thanks to this, PU systems have long been associated with offering strength, durability and resilience when faced with a variety of testing conditions, such as heavy footfall, physical impacts, extreme temperatures and corrosive chemicals.

PU systems are therefore very well suited to industrial facilities, where the floor is likely to face a long list of challenges on a daily basis. For example, just a hand pallet truck when fully loaded could weigh in excess of one tonne, which puts a vast amount of pressure through its wheels and into the floor. The robust nature of PU systems means that they can survive the abuses of industrial operations for a very long period of time.

Epoxies on the other hand are much more rigid in terms of structure and cannot tolerate intense heat as well. To exemplify this, some epoxy coatings are heat resistant to temperatures up to 65°C, whereas PU systems are available that can tolerate 120°C.

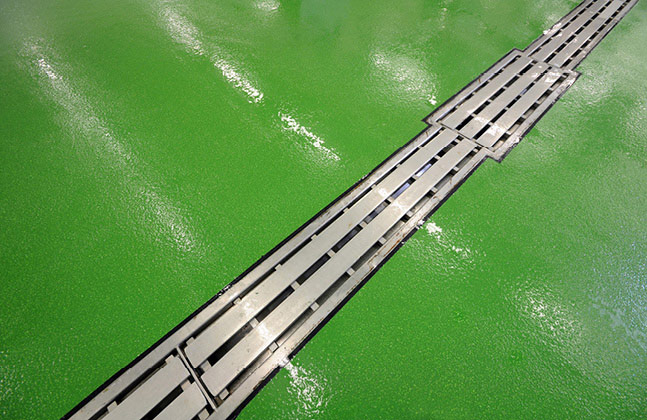

The superior chemical resistance of PU floors has made them popular in the food & beverage industry, where corrosive acids and by-products are found in large quantities. This means that floors are required that can stand up to chemical attack from organic acids as well as sugar, malt, caustic and powerful cleaning agents.

At this point it might seem like PU is the superior option, however what they give in durability they take away in versatility and aesthetics. Epoxies can be very easily adapted for a wide variety of environments and are available in a much wider range of colours, styles, effects and decorative options.

Unless there is a specific challenge or requirement for a PU, there will more than likely be an epoxy floor that is up to the task at hand, and which can do so in bright and glossy tones, glittering light reflective surfaces or multi-toned swirling shades.

This gives designers the creativity to install unique floors that convey the interior design scheme. This is a particularly good way to represent a brand identity, specific aesthetic or to infuse the environment with the desired vibe. This has made epoxies a go-to floor for large-scale commercial venues such as shopping centres and airports as well as in less heavy-duty industrial spaces or for customer-facing processing zones that need to look good as well as be functional.

PU systems also tend to be thicker and heavier than epoxies, which is great for absorbing impacts and thermal shock, but if weight and space is an issue then epoxies offer a thinner and lighter option.

Just to confuse issues further, when talking about PU it’s important to bear in mind that there are a few different types. There are full PU “liquid vinyl” type floors, which are great for creating soft surfaces underfoot due to the elastic nature of PU. However more common are PU deck coatings used for car parks and PU concrete systems, which are the most failure resistant type of resin flooring available.

PU concrete is often the one found in challenging industrial facilities as it is great at withstanding punishing impacts, extreme temperatures, heavy loads, harsh chemicals and the like. It can also be customised with anti-slip aggregates, anti-bacterial additives and is highly adept at dealing with rising moisture. As already mentioned it’s just not very pretty and unless it has an aliphatic coating it isn’t particularly colour stable.

In summary, it’s not so much a case of which one is better, as it’s really about which one is better for the building in question. To find out more about what resin floors best suit a specific environment, get in touch with the resin flooring specialists Flowcrete today.

ENDS

Enjoy this post? Click below to share it with your network:

Press Contact

For further information please contact [email protected]

Notes to Editors

Flowcrete is a world leader in the manufacture of seamless industrial and commercial resin flooring solutions. Flowcrete is now part of Tremco Construction Products Group.

Tremco CPG's leading brands have served as the benchmark for excellence and quality products since our first entry of our brands into the Australian region in 1984. Our commitment to serving our clients in a variety of areas with innovative and strategic technology products has allowed us to consistently grow for over 40 years.

Tremco CPG Australia is part of RPM International Inc. and our leading brands include Flowcrete, Tremco, Duram, illbruck, Nullifire, Dryvit, Nudura and Euclid Chemical.

For further information please contact [email protected]

Or visit us on the web at www.tremco.com.au