The Importance of Resin Flooring within the Safe Design of a Food Processing Facility

Food safety is vital for consumer confidence and the hygienic design of food processing facilities is central to the safe production of food and beverage products.

In this guide, we will cover the typical consideration factors when designing a food and beverage facility, including recommended resin flooring options.

|

Table of Contents |

Why Do I Need a Protective Flooring System?

The floor of food and beverage processing facilities and factories are subject to a wide variety of food by-products, including fats, hot oils, blood, sugar solutions and natural food acids. Many of these substances can cause substantial and cumulative damage to an uncoated concrete floor due to their corrosive nature. These substances can infiltrate the concrete material, resulting in microbial growth and the spread of bacteria. Over time, this will degrade the food production environment and may contaminate the food products themselves.

On top of this, aggressive cleaning and maintenance processes including steam cleaning, power washing, hot water washdowns and the use of harsh cleaning agents can put a significant amount of stress on the floor.

On an uncoated concrete surface, these cleaning processes can lead to significant damage to the substrate below. Steam cleaning and hot water washdowns are likely to put undue stress on the concrete slab and power washing will begin to eat away at the surface and expose the concrete’s weakness. Additionally, the use of aggressive cleaning chemicals corrodes the unprotected concrete, leaving it ripe for bacterial penetration as it becomes more and more porous.

For all of these above reasons, it is important that exposed concrete slabs are covered with a high-performance flooring system. Today, seamless resin floor finishes are increasingly specified in these food and beverage production environments because of the material’s hygienic profile and hardwearing performance characteristics.

Consider these Factors when Choosing a Protective Resin Flooring System for Food Production Facilities

Understanding the operational criteria and service requirements of the food and beverage facility or area in question is critical to determining what type of resin flooring system is suited. We begin by understanding what is required by food safety standards.

Floor Hygiene

Resin flooring systems offer an enhanced hygiene performance resulting from a seamless finish combined with the material’s excellent durability and performance.

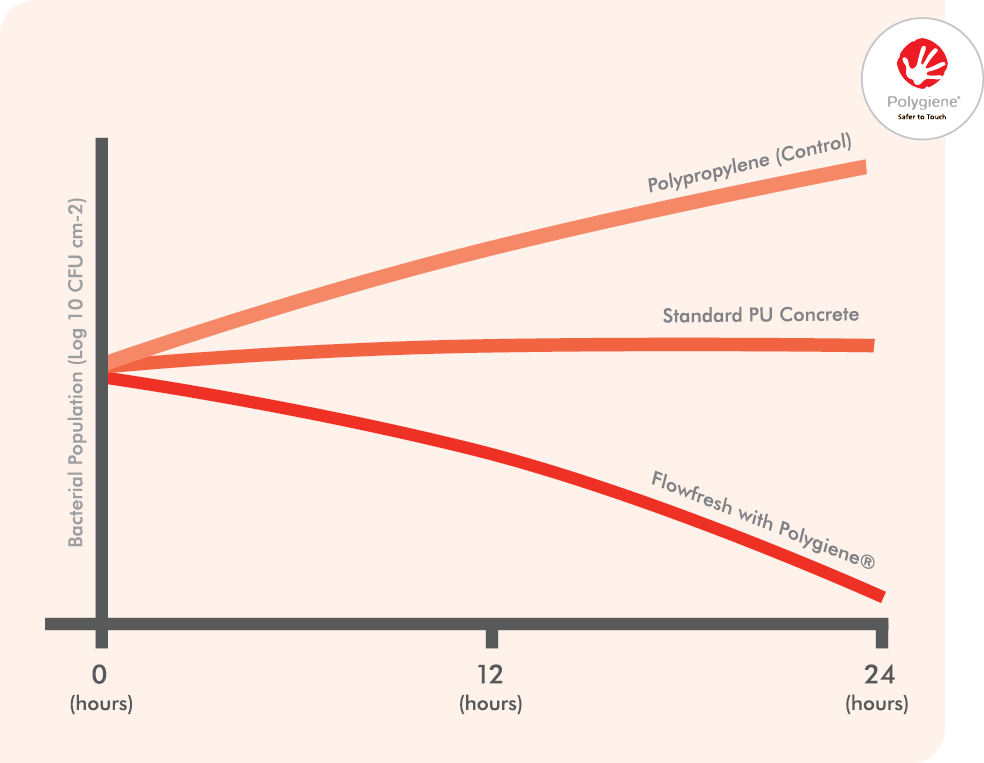

Flowcrete has developed further innovations that give the finished flooring surface better effectiveness at maintaining clean floor hygiene. The Flowfresh polyurethane flooring system contains Polygiene®, an antimicrobial agent that is homogeneously distributed throughout the resin matrix of a polyurethane flooring system to enhance on-site hygiene levels and offer complete surface protection against harmful bacteria, mould and yeasts.

Flowcrete has an exclusive partnership with Polygiene® – a manufacturer of natural silver ion-based antimicrobial additives. Polygiene® can positively inhibit the growth of gram-positive and gram-negative bacteria including E-coli, MRSA, C.difficile and Salmonella typhi amongst others. International studies show a 99.9% reduction in the bacterial population on the surface of a polyurethane floor containing Polygiene®.

Unlike many antimicrobial alternatives, this antimicrobial protection remains active for the lifetime of the floor, even if worn or damaged, offering a long-term hygiene performance.

Antimicrobial Activity After 60 Wash Cycles

FIGURE 1: Japanese Industrial Standard JIS Z 280:2000 measures the survival of bacterial cells on cementitious polyurethane with Polygiene® and compares this to polyurethane concrete containing no antimicrobial additive and an untreated polypropylene control.

HACCP Requirements

The Hazard Analysis and Critical Control Point (HACCP) food safety management system is a preventative risk assessment tool operated by the food industry to ensure that all food safety hazards are assessed and that appropriate controls are put in place to eliminate or reduce contamination of food from those hazards. It is a regulatory requirement in many parts of the world, including Australia, and is a demand placed upon the whole food chain as a means of demonstrating due diligence.

Getting the floor area correct is a critical part of implementing an effective HACCP food safety management plan, as otherwise this part of the facility can present a variety of challenging health and safety concerns - especially for large scale industrial facilities where slip risks, contamination threats and potentially dangerous working practices all need to be carefully accounted for.

The material chosen to provide a protective floor coating plays a much larger role in food safety that one might originally suspect and should be taken seriously during the design and specification stage. The HACCP International certification program highlights the importance of seamless and impervious flooring, as seams, joints, grout lines and gaps can become breeding sites for bacteria, fungi, mould and mildew.

It is also critical that the floor is able to maintain the highlighted properties of being seamless and impervious, robust enough to stand up against chemicals, cleaning regimes, thermal shock, slip resistance, heavy foot traffic and point loading for an extended period of time so that the floor is not compromised and degraded by the site's day-to-day activities.

Slip Resistance

It is imperative that within food manufacturing and preparation zones, as well as staff breakout areas and amenities, all floors have non-slip surfaces to prevent slips and trips that may result in work injuries.

In wet service environments, it is even more critical to ensure that the flooring system is tested under these conditions to determine that the flooring will provide the correct level of work safety. Also, for wet service environments, the floor design should be laid to falls leading to an efficient drainage system to prevent the pooling of water and minimise the risk of slips.

Specifiers of food and beverage manufacturing, processing and packaging facilities should have a clear understanding of local Australian slip resistance requirements. The following should be consulted to determine what level of slip resistance is required;

- AS4586-2013

- National Code of Construction (NCC)

- SA HB 198 2014.

Resin flooring is available in a range of textures and can be graded with broadcast aggregates to increase the anti-slip profile of the flooring system. However, coarsely textured surfaces (such as positively graded resin flooring systems) are more difficult to maintain cleanliness, so the correct method of cleaning and choice of sealer is critical. The correct cleaning and maintenance program will ensure that your new floor retains its appearance and helps to extend the working life.

Cleaning & Maintenance

Floors in the food industry are known to typically take more abuse than other surfaces within the food industry, as a result of the prevalence of various chemical substances and punishing conditions.

For this reason, an effective cleaning and maintenance routine should be in place to preserve the overall aesthetic, cleanliness and performance of the resin floor finish. Generally, resin flooring will not be affected by most special-purpose cleaning products when these are used in accordance with the Chemical Cleaning Manufacturers’ instructions. Specific cleaning instructions should also be sought from the resin flooring manufacturer.

A small spot test in an inconspicuous area is a worthwhile precaution before using a new cleaning product. The cleaning regime should also specify the type of equipment to be used, the type of cleaning chemicals to be used, and the frequency of the cleaning.

It is important to note that cementitious polyurethane systems are compatible with steam cleaning and hot water washdown cleaning methods, however, these cleaning methods are not recommended for epoxy systems or MMA systems.

The equipment used for the care and maintenance of your resin floor finish should be commensurate with the area involved and should incorporate, wherever possible, mechanically or electrically driven equipment/machines that are designed. 'Cleaning' can embrace a whole range of activities, from damp mopping of small, lightly soiled areas to heavy-duty machine scrubbing for the removal of ground-in dirt or compacted oil and grease. To be effective, the equipment which is used should be appropriate for the size and nature of the tasks to be undertaken. When selecting the equipment, consideration must be given to the type of surface to be cleaned, especially those with a slip-resistant/textured finish.

Nature of Chemical Contact

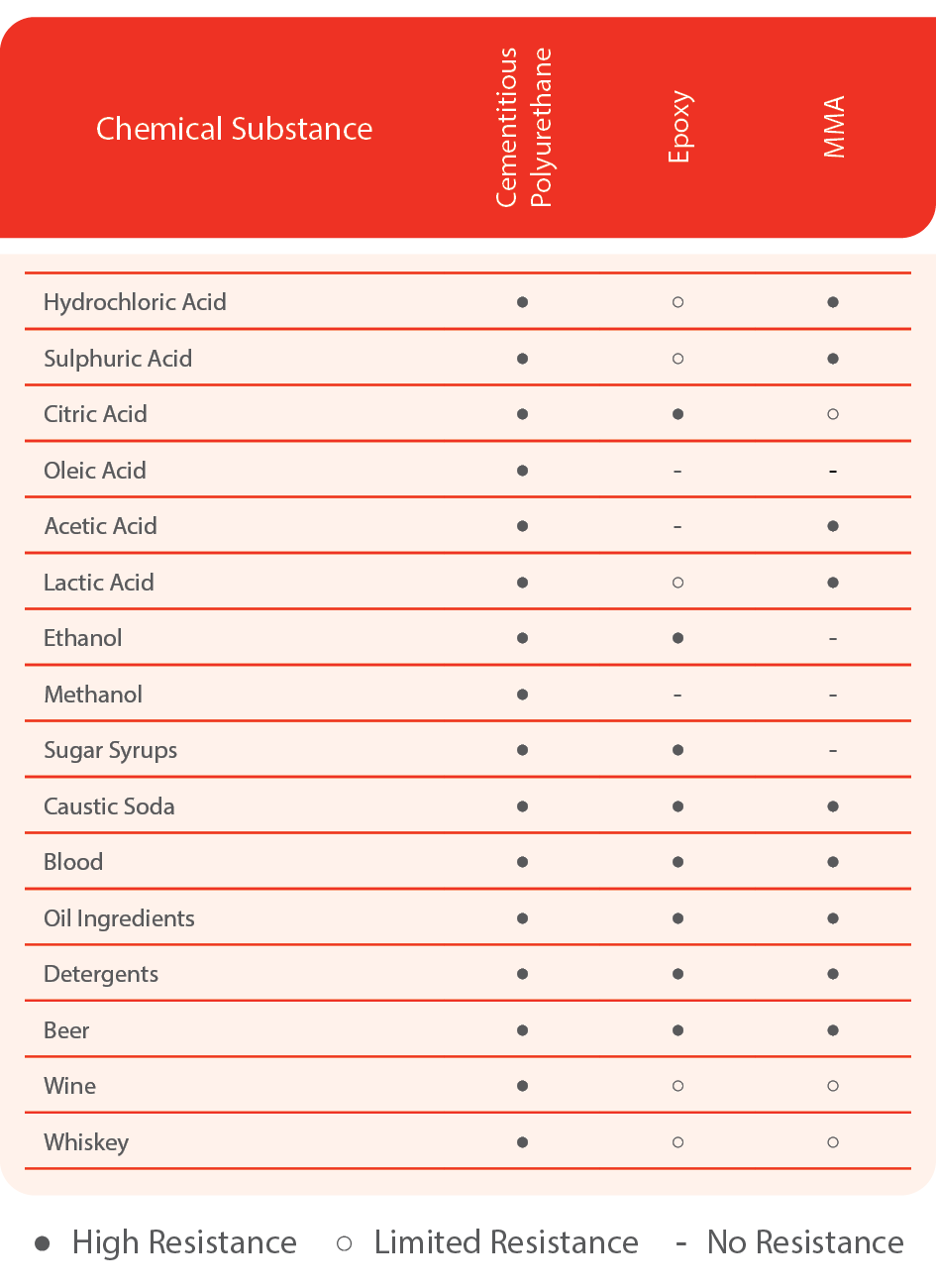

A wide range of organic and inorganic acids, alkalis and salts, as well as hot oils, blood, sugars and fats are commonly present in food and beverage production facilities, making these production environments susceptible to chemical attacks.

Failure to anticipate the prolonged nature or degree of chemical attack may result in erosion of the surface, softening or embrittlement as well as blistering or delamination.

Factors affecting the chemical resistance profile of a resin flooring system including its thickness, resin/polymer basis and reactivity of the chemical agent.

By far and away, the most effective and extensive method of protection against chemical attacks is a polyurethane flooring system, also known as a PU screed. Polyurethane flooring offers a significantly enhanced resistance to corrosive substances, solvents, foodstuff by-products, organic acids and many others.

Epoxy resin flooring systems and methyl methacrylate resin flooring systems have their levels of resistance to different types of chemical substances, as seen in the following chemical resistance comparison table.

FIGURE 2: Chemical Resistance of Resin Flooring Comparison Chart by Flowcrete Group Ltd, 2013.

FIGURE 2: Chemical Resistance of Resin Flooring Comparison Chart by Flowcrete Group Ltd, 2013.

Thermal Shock & Cycling

As part of their operations, food and beverage manufacturing plants and certain agricultural facilities can experience thermal shock conditions, which can lead to floor failure if the incorrect flooring material has been specified.

Thermal shock occurs when the flooring of food processing facilities that normally remain at ordinary room temperatures are cleaned with very hot water or steam to remove stubborn blood, grease and other chemical contaminants. The rapid change of temperature will cause the floor finish to expand or contract at a different rate than the substrate. If the facility flooring material does not have sufficient thermal shock resistance, at some point, the floor coating structure will start to fail, leading to cracks, bubbling, peeling or delamination.

In particular, for cold stores and blast freezers, and areas with furnaces and ovens, an appropriate flooring system is required to withstand the long periods of exposure to temperatures outside of the ordinary range. In these operating environments, thick cementitious polyurethane flooring systems are suitable to meet the requirements.

This is because cementitious polyurethane systems are much better equipped to deal with thermal shock and extreme temperature fluctuations than epoxy systems or methyl methacrylate systems. Polyurethane systems have a coefficient of thermal expansion that is similar to that of concrete, allowing the material structure to expand, contract and move with the substrate, preventing any lasting damage.

What Resin Flooring Options are Available for Food and Beverage Factories?

This is a common question faced by industrial facilities managers and plant operators working within the food and beverage industry. Flowcrete resin flooring systems are available in a wide range of colours and performances and have been designed to best meet the different working areas within a food and beverage production plant - all of which will be subject to different operating conditions.

Cementitious Polyurethane

Cementitious polyurethane flooring systems, also known as polyurethane (PU) screeds, are a popular choice for clients within the food industry. A typical polyurethane material used in this application comes in mortar form, combining cement and water-based technologies that exhibit a high cross-linked density and resistances, making them ideal for abusive environments subject to prolonged chemical attacks.

Also, polyurethane resin systems exhibit a thermal coefficient of expansion that is similar to concrete. This offers excellent benefits when installed directly over concrete in environments subject to thermal shocks and thermal cycling as it prevents the material from cracking when subject to large and rapid temperature swings.

Importantly, cementitious polyurethane resin flooring systems are non-porous, preventing bacteria and mould spores from surviving in joints or cracks that are typically found in alternative flooring systems such as tiles or acid bricks. They are also low odour, non-toxic and non-hazardous.

Methyl Methacrylate (MMA)

Methyl methacrylate (MMA) flooring systems for food manufacturing and processing plants are notable for their ability to cure at fast speeds and be installed at extremely low temperatures. MMA resin can fully cure within one to two hours, making it an ideal choice for operational production facilities looking to minimise downtime and disruption, as well as fast-track new-build construction projects.

In addition, MMA resin material demonstrates a high level of UV light resistance as well as possessing chemical resistance to a range of acids and alkalis. Although MMAs have a unique odour, the odour is harmless and can be minimised with proper ventilation during installation.

Epoxy

Epoxy floor coatings are two or three-component systems that are typically trowel or roller-applied, and are available in a wide variety of colours. Epoxy coatings can also be broadcast with aggregates to deliver a slip-resistant floor finish.

While epoxy coatings offer limited resistance to organic acids (commonly found in natural food products), they offer no resistance to thermal shock, making them susceptible to thermal shock failure, which will result in cracking and de-bonding of the floors. Therefore, epoxy coatings are not usually the best flooring options in rigorous food and beverage processing environments.

Epoxy resin floor coatings are good choices for non-processing zones of food manufacturing facilities that are not subject to the same high protection demands, which includes areas for packaging, maintenance and staff breaks as well as corridors, lobbies and office spaces.

Flowcrete Case Studies: Flooring for Food and Beverage Factories

Flooring for the food industry is an important topic with many sensitive areas of concern to meet food safety standards. Check out the F&B industry case studies around the Australia and Pacific regions, where Flowcrete flooring systems are used for flooring new-builds and overhauls.

This guide has been produced to give an overview of the resin choices available and factors to consider when choosing a resin flooring system for a food and beverage manufacturing, processing or packaging facility.

Detailed recommendations and advice are available from our network of regional technical and sales representatives.